Golden Horn Unkapanı tube tunnel

Project description

The tunnel cross section would accommodate two traffic tubes with 3 lanes each and a central gallery with a section for evacuation in the lower part and smoke extraction in the upper.

The geology in the Golden Horn is characterized by 30-40 m soft layers on top of weathered sandstone and siltstone. The riverbed is at 35 m below water level and considered deep. Due to the combination of steep slopes, dense population and the need to connect to the boulevards a tunnel below riverbed was not possible. A submerged tube bridge was therefore the most suitable option. For local shipping a navigation channel of 8.5 m deep and 300 m wide had to be accommodated.

Due to the vicinity of the North Anatolian Fault the design had to meet severe seismic design criteria. In order to reduce both internal forces and deformations in a reasonable manner, the tunnel was designed as a ‘limited flexible’ structure, meaning that connections would have sufficient flexibility to accommodate differential displacements, with restraints that are activated gradually.

Based upon a reference design and tender requirements the Tender Design was developed which was dictated by the seismic circumstances requiring special joint detailing. For the longitudinal tunnel design, this resulted in a layout of one short permanent prestressed tunnel element at each end and connected to the land tunnel abutment and with longer tunnel elements in between. The immersion joints (joints between the tunnel elements) are prestressed after immersion. A special flexible joint was developed at both abutments allowing for displacement of +/- 0,5 meter.

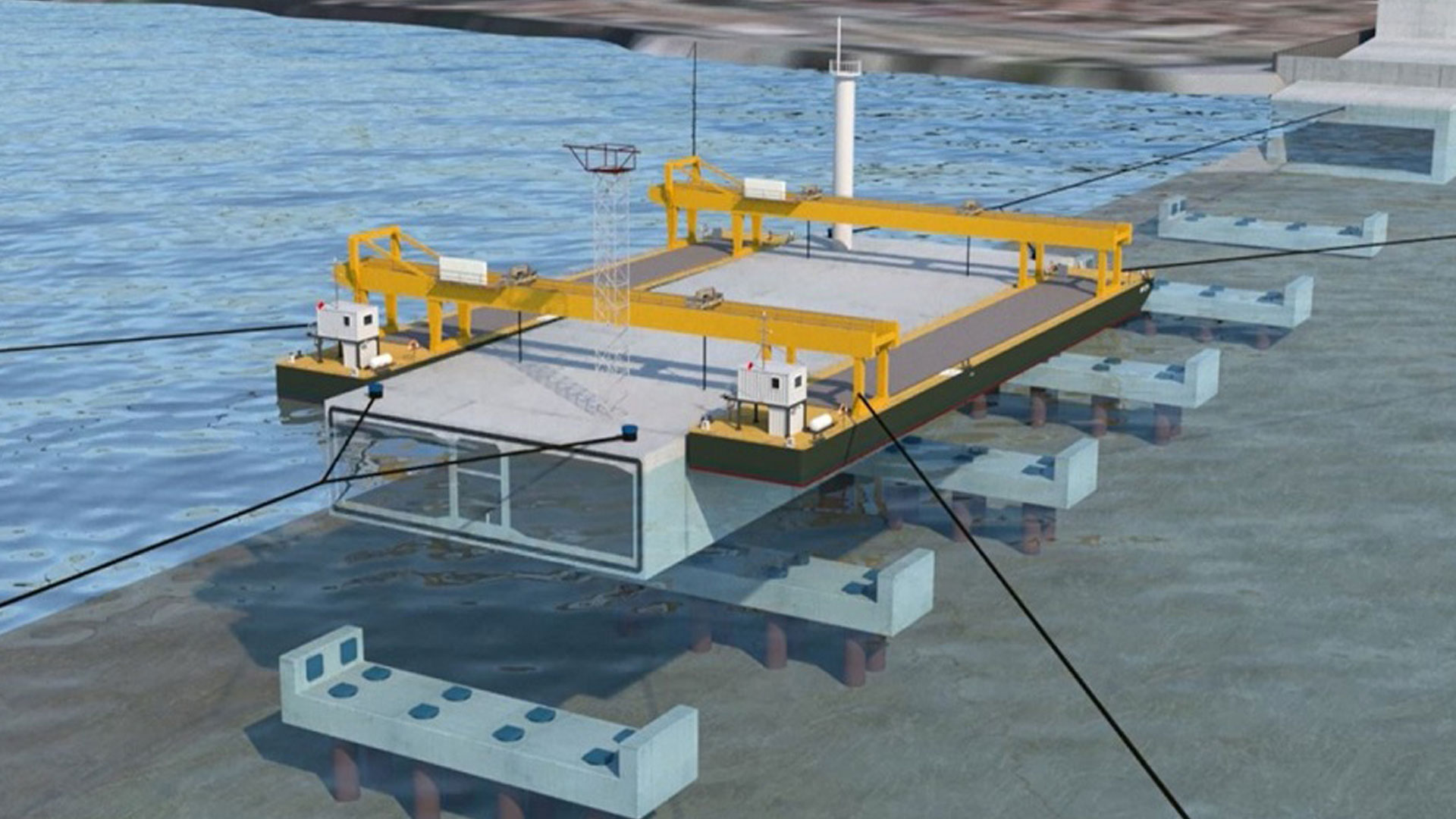

The tunnel elements are supported by pile bents consisting of 2.5 m diameter steel piles with a socket into the rock and precast capping beams installed with suitable marine works equipment. The elements will be constructed on a different location under semi-floating conditions and after completion transported to the site in Istanbul over approximately 40 kilometres.

After the construction tender submission IBB selected the joint venture Yapı Merkezi-STFA-ASL Inşaat Group to build the tunnel, with TEC as design and engineering consultant. Because of changing political priorities, the project was put on hold shortly after the selection of the successful bidder.

Scope of work

TEC supported by a local Turkish partner was responsible for the tender designs for:

- the immersed tunnel including the foundation structures (civils)

- the tunnel installations (MEP)

- the temporary works for the construction, transportation and immersion of the tunnel elements

- the interfaces at the abutments with the in-situ tunnel.

Special attention was given to the seismic design which was performed with use of the FEM program SAP-2000.

Project facts Golden Horn Unkapanı tube tunnel

- ClientYapı Merkezi-STFA-ASL Inşaat Group

- LocationIstanbul

- In co-operation withLocal Turkish partner

- Project duration2016-2017

- CountryTurkey

- Project phaseTender design